When purchasing a car wrap (Car Wrap / Paint Protection Film, PPF / Color Changing Vinyl Wrap), most buyers focus on color, thickness, and price, but often overlook a critical factor affecting durability and performance: the adhesive base material.

The quality of the adhesive layer not only determines whether the wrap is easy to install and stays bubble-free, but also affects whether it leaves residue or damages the original paint upon removal.

This guide will help you:

- Learn how to judge adhesive quality

- Understand the most suitable adhesive for different film types

- Choose cost-effective solutions based on purpose and budget

1. Why the Adhesive Base Material Matters

The adhesive layer is the core component that keeps the wrap adhered to the car surface. Even premium film material cannot perform well if the adhesive is poor quality.

Potential issues caused by low-quality adhesive:

- Bubbling, peeling, or lifting edges

- Residue after removal, potentially damaging original paint

- Degradation under heat, humidity, or UV exposure

- Difficult installation, poor fit on curves and recesses

- Damage or residue during removal

Thus, evaluating adhesive quality is essential when choosing a car wrap.

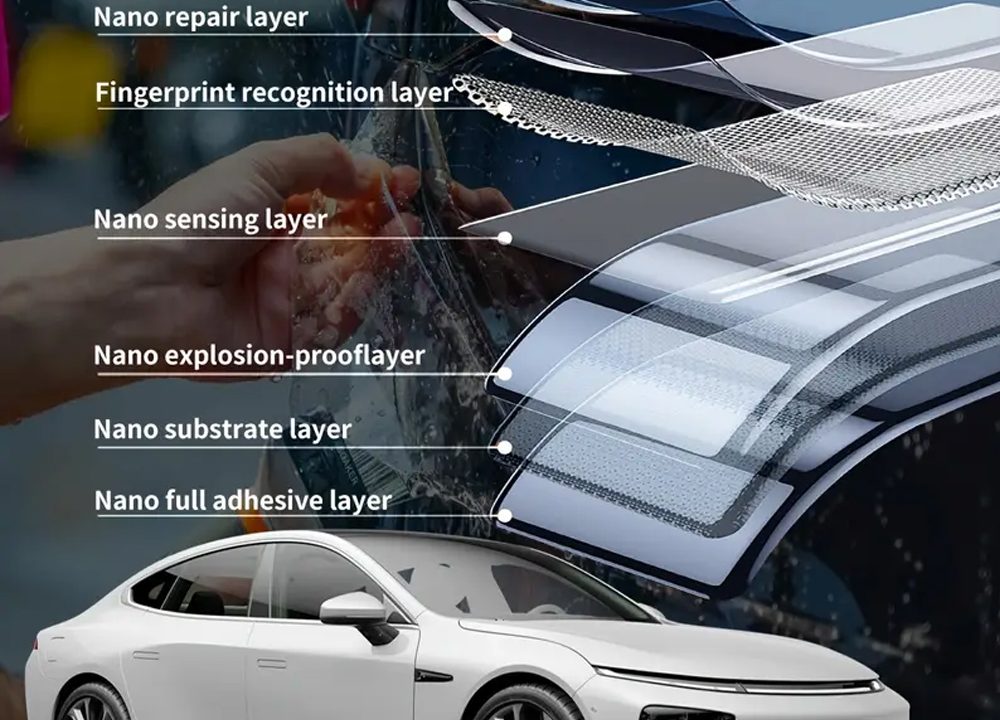

2. Types and Composition of Adhesive Base Materials

2.1 Pressure Sensitive Adhesive (PSA)

- Most common type, activated by pressure, allowing adjustment during installation

- Usually acrylic-based (Acrylic PSA)

- Variants: solvent-based (stronger adhesion, better weather resistance) and water-based (low VOC, eco-friendly, slightly lower durability)

2.2 Heat-Activated Adhesive (HAA)

- Requires heat to activate adhesion, uncommon for full vehicle wraps

- Poor adjustability, higher installation difficulty

2.3 Microstructured Air-Release / Honeycomb Adhesive

- Common in premium films, contains microchannels for air release

- Reduces bubbles, ensures smoother installation

2.4 Removable / Low-Residue Adhesive

- High-quality wraps are designed to leave minimal or no residue upon removal

- Maintains performance even after aging tests

3. Evaluation Standards: Buyer Checks and Manufacturer Data

| Indicator | Meaning | Ideal / Reference Value | Buyer Check Method |

|---|---|---|---|

| Initial Tack | Adhesion strength immediately after applying | ~1000–1500 g / 25 mm (GB31125-2014) | Manufacturer report or sample testing |

| Peel Strength | Resistance to lifting after adhesion | ~7 N / 25 mm | Request peel strength data |

| Holding Power | Ability to maintain adhesion under heat/humidity | Hours/days without lifting | Test sample in high-temperature environment |

| Aging / Residue Test | Residue after exposure to time and temperature | No residue after thermal & ambient aging | Request aging report or test sample |

| Air Release / Bubble Channels | Microchannels to reduce bubbles | Present | Apply film to metal/glass to observe bubble release |

| UV Resistance | Adhesive stability under sunlight/UV | Stable for years | Manufacturer UV aging test report |

| Chemical Resistance | Reaction to fuels, oils, cleaning agents | Stable, no discoloration or loss of adhesion | Wipe sample with common automotive chemicals |

4. Practical Buyer Guide: How to Verify Adhesive Quality

4.1 Procurement Stage: Request Samples

- Ask suppliers for small sample pieces (e.g., 20×30 cm) with adhesive included

- Verify batch number, adhesive test report, and aging/residue report

- Check for “Low Residue / Clean Removal” label

4.2 Sample Testing

- Adhesion Test: Apply sample on clean metal or painted panel, press and peel to check ease of removal

- Thermal Aging Test: Store at 60–80°C for a few days, then peel; also test low-temperature adhesion

- Chemical Test: Wipe edges with fuel, alcohol, car wax, or wash solution to check adhesive stability

- Repeat Peel Test: Peel and reapply in the same area to observe any loss of adhesion or residue

4.3 Installation Stage Verification

- Ensure smooth application without trapped bubbles

- Check tight fit on curves and recesses; no lifting edges

- Observe edges for lifting a few days post-installation

4.4 Long-Term Observation

- Monitor for peeling, bubbling, or lifting during sun, rain, or washing

- Check for residue or damage when removing the film

5. Recommended Adhesive for Different Wrap Types

Color Changing Film (PVC / PET)

Adhesive: Air-Release Adhesive

Advantages: Easy to install, cost-effective, ideal for short-term color change (2–4 years)

Suitable for buyers wanting vehicle personalization on a budget

Paint Protection Film (TPU)

Adhesive: High-durability Acrylic Adhesive

Advantages: Elastic, self-healing, long-lasting 5–10 years

Suitable for buyers seeking long-term paint protection, premium vehicles

Window / Partial Film (PET)

Adhesive: Optical Clear Adhesive (OCA)

Advantages: High transparency, UV resistance, good value

Suitable for buyers wanting heat insulation, UV protection, and clear visibility

👉 [Insert comparison table of TPU / PVC / PET + Adhesive + Pros/Cons + Recommended Buyers]

FAQ

Q1: How can I tell if the adhesive will leave residue?

A: Look for “Removable / Clean Removal” on the product label; top brands provide residue test reports.

Q2: Can TPU be used for color-changing wraps?

A: Yes, but it’s expensive; PVC/PET is more cost-effective for short-term color changes.

Q3: How to avoid bubbles during installation?

A: Use adhesive with micro air-release channels, maintain proper temperature, and apply correct technique.

Want to learn more about film materials and adhesive selection? Visit our website for technical guides, sample requests